- Site Navigation -

NEWS

NEWS INFORMATION

exploring Fiberglass Cloth: from production process to industry applications

Author:Shuoer Date:2025-05-10 16:07:49 Hits:179

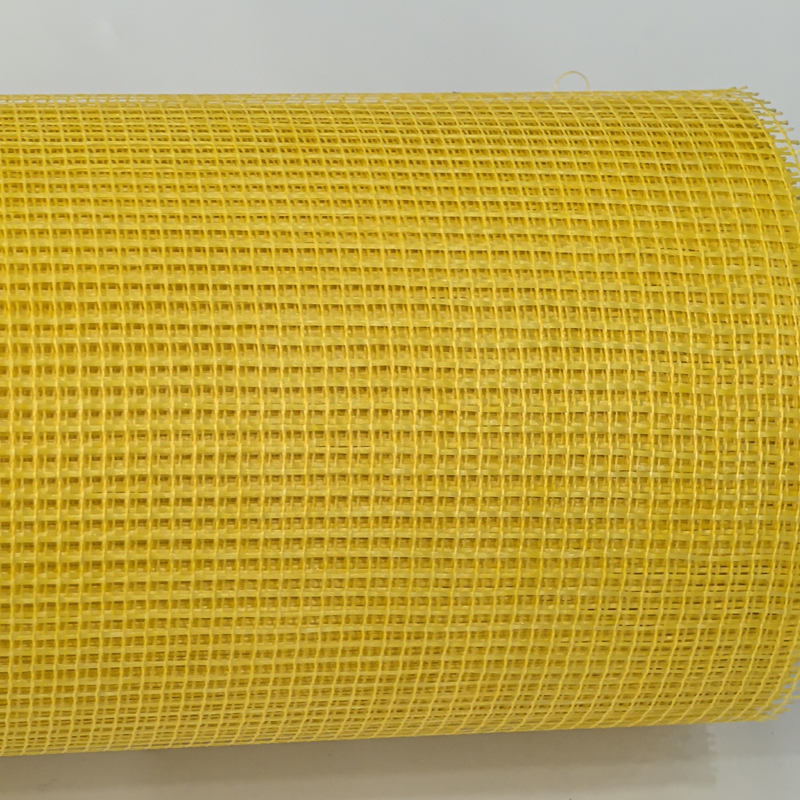

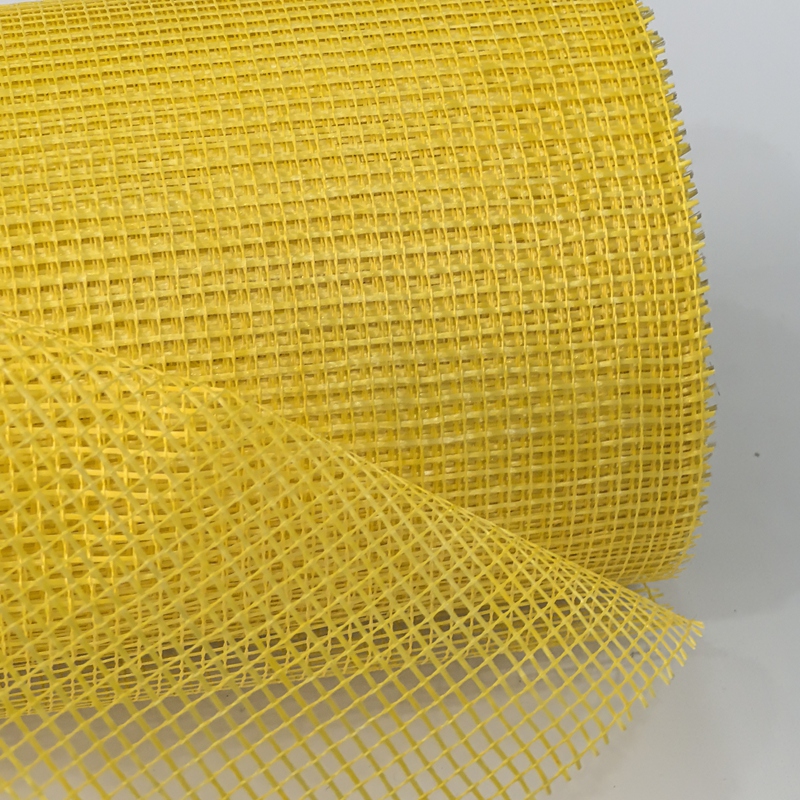

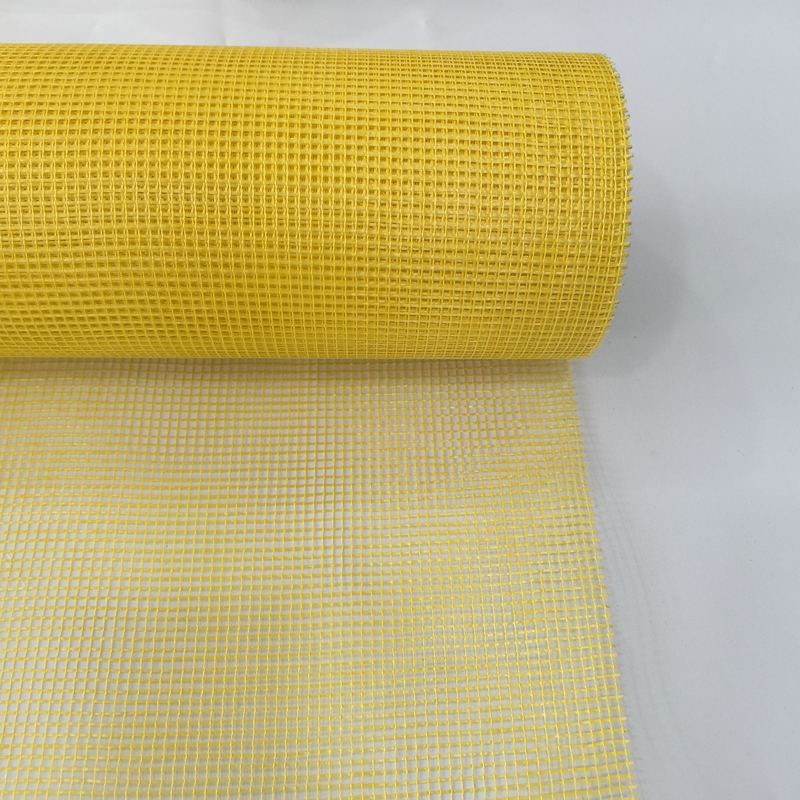

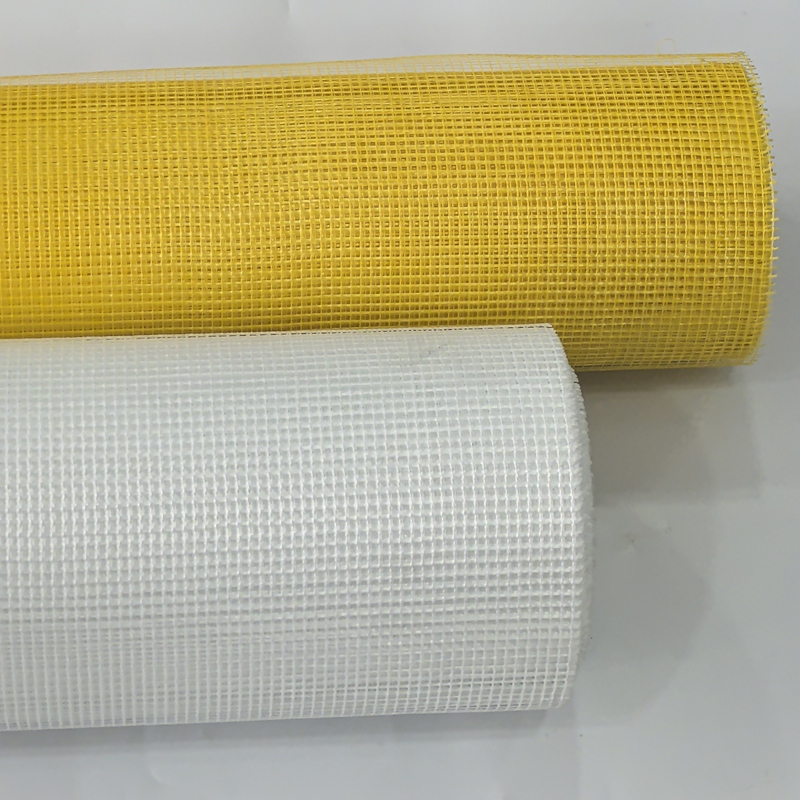

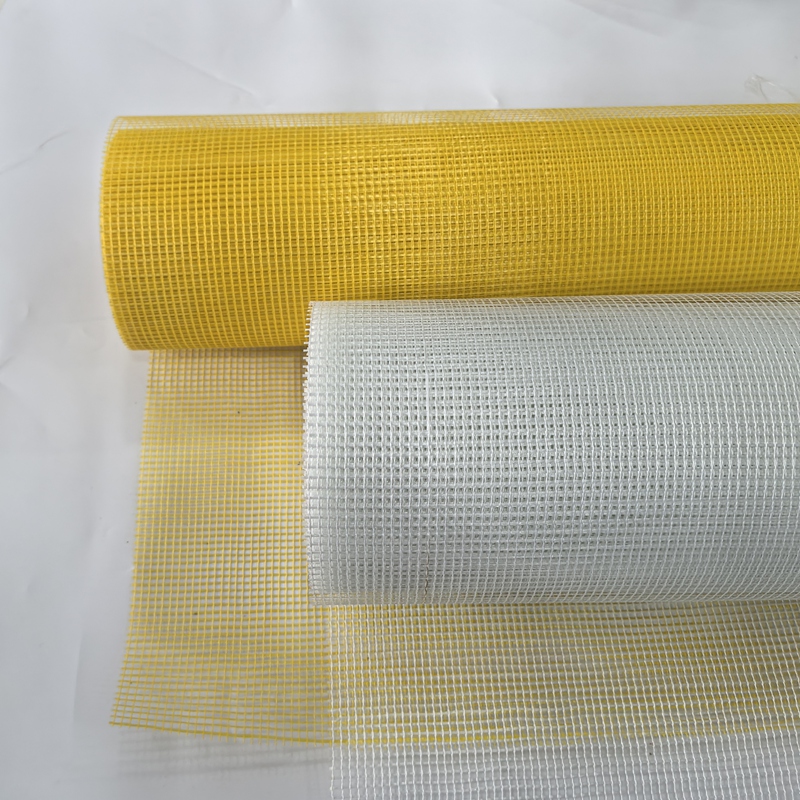

Glass fiber cloth, also known as fiberglass cloth, is a type of fabric woven from fiberglass as raw material. It has high strength, high temperature resistance, corrosion resistance, good insulation properties, and is widely used in various fields such as industry, construction, transportation, electronics, and environmental protection. This article will comprehensively analyze glass fiber cloth from the aspects of production technology, performance characteristics, and industry applications.

1、 Production process of glass fiber cloth

The production process of glass fiber cloth mainly includes the following key steps:

raw material preparation

The main raw material of glass fiber cloth is glass fiber, usually made from mineral materials such as quartz sand, limestone, boric acid, etc., which are melted at high temperature and drawn. The diameter of glass fiber is generally several micrometers to tens of micrometers, and it has excellent mechanical properties and chemical stability.

Wire drawing process

High speed drawing of molten glass into glass fiber monofilaments through a leak plate. The wire drawing process is the core link in the production of glass fiber cloth, which directly affects the quality and performance of the fibers. In modern production, the pool furnace drawing method is commonly used, which has the advantages of high production efficiency, low energy consumption, and stable fiber quality.

weaving process

Weave glass fiber monofilaments into fabric using a weaving machine. According to different needs, glass fiber cloth can be woven using plain weave, diagonal weave, satin weave and other weaving methods. During the weaving process, it is necessary to control the warp and weft density and tension to ensure the flatness and strength of the fabric surface.

post-treatment

The woven glass fiber cloth needs to undergo post-treatment, including heat setting, surface treatment, coating, etc. Heat setting can eliminate internal stress in fabrics and improve dimensional stability; Surface treatment can improve the bonding performance between fibers and resins; Coating treatment can endow fabrics with special functions such as waterproofing, fireproofing, and anti-corrosion.

2、 Performance characteristics of glass fiber cloth

high strength

The tensile strength of glass fiber cloth is much higher than that of ordinary fabrics, and it has excellent mechanical properties, making it suitable for high-strength applications.

High temperature resistance

Glass fiber cloth can be used for a long time in high temperature environments, with a melting point usually above 500 ℃. Some high-performance products can withstand temperatures above 1000 ℃.

corrosion preventive

It has good corrosion resistance to chemicals such as acids, bases, and salts, and is suitable for corrosive environments such as chemical and environmental protection.

good insulation

Glass fiber cloth is an excellent electrical insulation material widely used in the field of electrical insulation.

dimensionally stable

The glass fiber cloth that has undergone heat setting treatment has good dimensional stability and is not easily deformed.

Strong designability

It can meet the needs of different fields by adjusting fiber diameter, fabric structure, post-treatment processes, etc.

Cangzhou ShuoerFiberglass Products Co., Ltd

Copyright © 2025-2026 http://www.shuoerglassfiber.com. All Rights Reserved Cangzhou Shuoer Fiberglass Products Co., Ltd

Current location:

Current location: